eurocrete HD (Formerly HF)

Heavy-Duty Hygienic Polyurethane Flooring

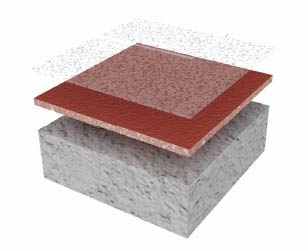

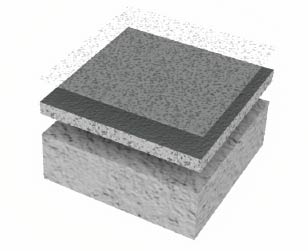

eurocrete HD is a high-performance polyurethane cement flooring solution, built for extreme durability and hygiene. Applied at a thickness of ¼” to ⅜”, it offers unmatched resistance to physical and chemical wear, lasting over 10 years with minimal maintenance.

This heavy-duty flooring outperforms concrete by protecting against impact, abrasion, thermal shock, and steel-wheeled traffic.

Talk to an Expert

Quick Data

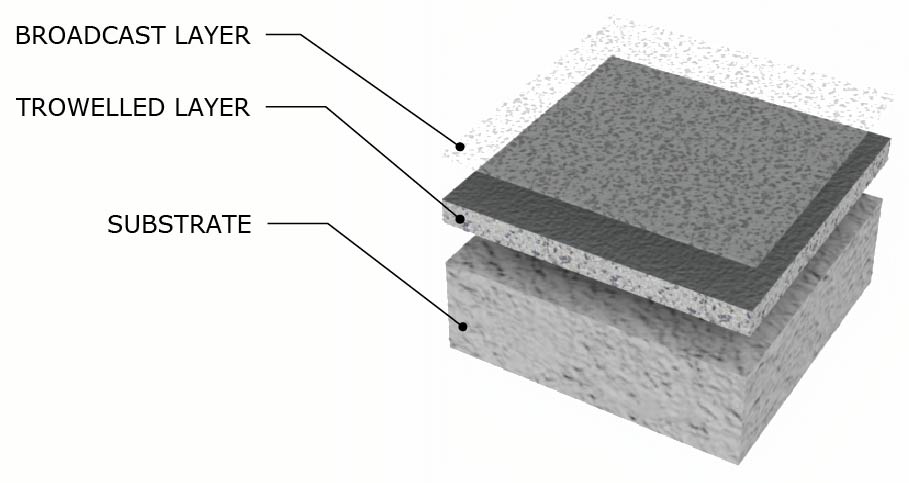

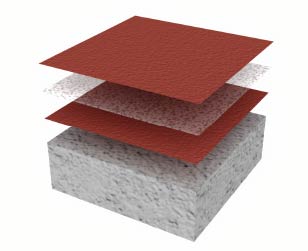

Appearance: eurocrete HD is trowel applied and broadcast with quartz to produce a heavy-duty, anti-slip surface with a matte finish. Top coat available for smoother finish.

Applications: Food processing plants, abattoirs, sausage factories, bakeries, dairies, breweries, and kitchens.

Durability: eurocrete HD is our highest durability product. Lifespan of ten or more years in the toughest environments. Completely non-porous, excellent chemical resistance and slip resistance – even in wet process areas. Impervious to substantial impact, abrasion, chemicals, and steel-wheeled traffic.

Thickness: 1/4” and 3/8” thick.

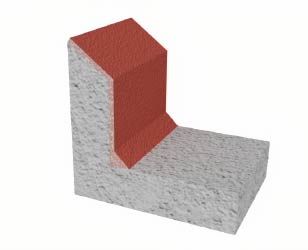

Substrates: Minimum: Concrete, polymer reinforced screeds, grano concrete, wood, or steel. Recommended: Captive shot blasting or diamond grinding.

Technical Documents

Benefits

Chemical

Resistance

Physical

Resistance

Easily

Cleaned

Slip

Resistance

Physical Data

Compression Strength | ASTM C 579 | 8,000 psi |

| Tensile Strength | ASTM C 309 | 850 psi |

| Flexual Strength | ASTM C 580 | 2,900 psi |

| Coefficient of Thermal Expansion | ASTM D 2047 | 1.1 x 10-5in/in/°F |

| Abrasion Resistance | ASTM D4 4060; CS 17 Wheel, 1000 cycles | 0.05g loss |

| Adhesion | ASTM D 4541 | 2.7 MPa (substrate facing) |

| Softening Point | 126° C | 260° F |

Cure Schedule

| Time to light traffic | 4-6 hours |

| Time to light wheels | 12-16 hours |

| Time to normal traffic | 24 hours |

| Time to heavy traffic | 3-5 days |

Toll Free: 1-877-513-5855

Toll Free: 1-877-513-5855 eurocrete SL

eurocrete SL eurocrete TC

eurocrete TC eurocrete WR

eurocrete WR eurocrete RT

eurocrete RT eurocrete LD

eurocrete LD