eurocrete WR

Chemically Resistant Polyurethane Wall and Cove Base Solution

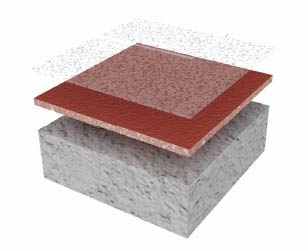

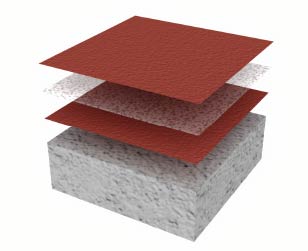

eurocrete WR is a trowel-applied cementitious urethane wall and cove base mortar. It is formulated for superior chemical and abrasion resistance. Utilizing advanced polyurethane technology, it ensures seamless integration with Eurocrete polyurethane flooring systems, maintaining consistent performance standards for walls and coving.

Talk to an Expert

Quick Data

Appearance: It is trowel applied to produce a finely textured smooth, uniform matte finish.

Applications: eurocrete WR is designed to be used with any other eurocrete floor system to ensure vertical or floor to wall transitions are protected. Food and Beverage, Pharmaceutical, Manufacturing, and other industrial or commercial settings where concrete curbs, walls and other vertical and floor to wall transitions need to be protected. eurocrete TF can be added as a top coat for improved clean-ability and aesthetics.

Durability: eurocrete WR offers the highest level of durability available. It is totally non- porous, has excellent chemical resistance, and its surface profile ensures easy clean-ability.

Thickness: 1/8” and 1/4” thick.

Substrates: Minimum: Concrete, wood, or steel. Recommended: Diamond grinding.

Technical Documents

Benefits

Chemical

Resistance

Physical

Resistance

Easily

Cleaned

Slip

Resistance

Physical Data

Compression Strength | ASTM C 579 | 7,500 psi |

| Tensile Strength | ASTM C 309 | 950 psi |

| Flexual Strength | ASTM C 580 | 2,200 psi |

| Coefficient of Thermal Expansion | ASTM D 2047 | 1.4 x 10-5in/in/°F |

| Abrasion Resistance | ASTM D4 4060; CS 17 Wheel, 1000 cycles | 0.07g loss |

| Adhesion | ASTM D 4541 | 2.7 MPa (substrate facing) |

| Softening Point | 126° C | 260° F |

Cure Schedule

| Time to light traffic | 4-6 hours |

| Time to normal traffic | 24 hours |

Toll Free: 1-877-513-5855

Toll Free: 1-877-513-5855 eurocrete SL

eurocrete SL eurocrete TC

eurocrete TC eurocrete RT

eurocrete RT eurocrete LD

eurocrete LD