eurocrete RT (Formerly HFS)

Heavy-Duty Hygienic Rake and Trowel Polyurethane Flooring

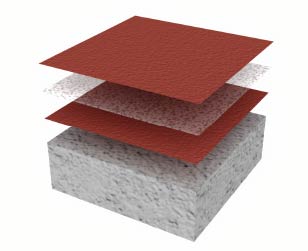

eurocrete RT is a high-strength polyurethane cement flooring system designed for environments demanding exceptional durability and chemical resistance.

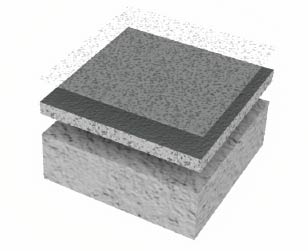

Applied at a thickness of ¼″ to ⅜″, this advanced flooring solution outperforms traditional concrete, offering a service life exceeding 7 years under extreme operational conditions.

Talk to an Expert

Quick Data

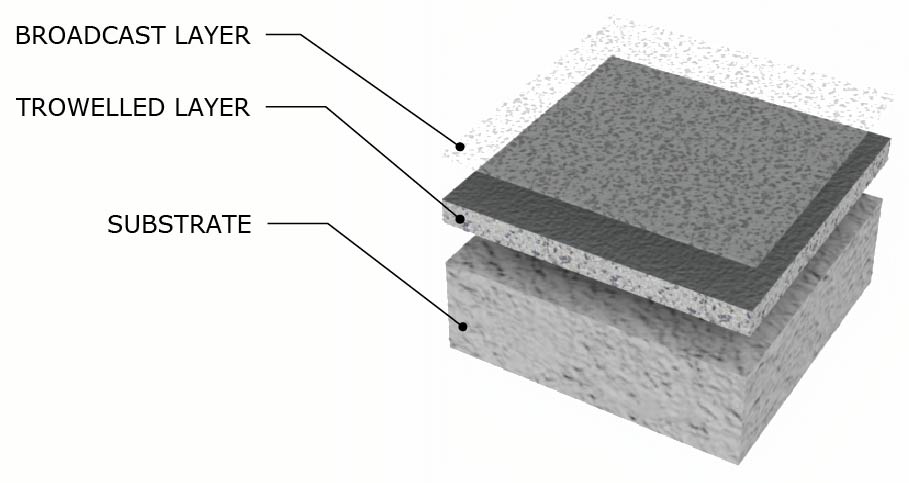

Appearance: It is rake and trowel applied to produce a heavy-duty, anti-slip surface with a matte finish.

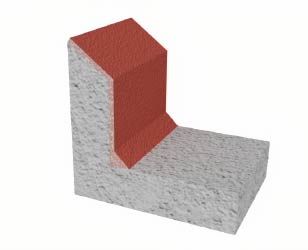

Applications: An ideal mortar for all concrete substrates and (up to) 1.5% slope grades; especially useful when working around stationary manufacturing equipment.

Durability: eurocrete RT offers the highest level of durability available. It does not support microbial growth, has physical properties of approximately double that of concrete. It tolerates a wide range of organic and inorganic acids, alkalis, and salts. It has a high bond strength that can withstand steam cleaning.

Thickness: 3/16” and 1/2” thick.

Substrates: Minimum: Concrete, polymer reinforced screeds, grano concrete, wood, or steel. Recommended: Captive shot blasting or diamond grinding.

Technical Documents

Benefits

Chemical

Resistance

Physical

Resistance

Easily

Cleaned

Slip

Resistance

Physical Data

|

Compression Strength

|

ASTM C 579 |

8,000 psi

|

| Tensile Strength | ASTM C 309 |

975 psi

|

| Flexual Strength | ASTM C 580 | 2,900 psi |

| Coefficient of Thermal Expansion | ASTM D 2047 | 1.1 x 10-5in/in/°F |

| Abrasion Resistance | ASTM D4 4060; CS 17 Wheel, 1000 cycles | 0.07g loss |

| Adhesion | ASTM D 4541 | 2.7 MPa (substrate facing) |

| Softening Point | 126° C | 260° F |

Cure Schedule

| Time to light traffic | 4-6 hours |

| Time to light wheels | 12-16 hours |

| Time to normal traffic | 24 hours |

| Time to heavy traffic | 3-5 days |

Toll Free: 1-877-513-5855

Toll Free: 1-877-513-5855 eurocrete SL

eurocrete SL eurocrete TC

eurocrete TC eurocrete WR

eurocrete WR eurocrete HD

eurocrete HD eurocrete LD

eurocrete LD