eurocrete LD (Formerly DBS)

Light-Duty Cementitious Urethane Flooring System

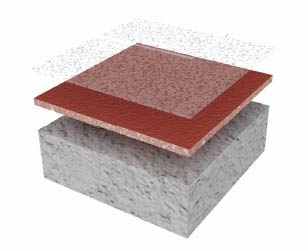

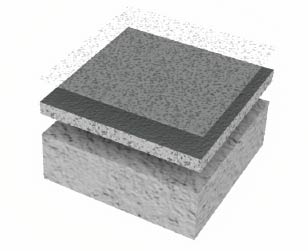

eurocrete LD is a roll applied, food-safe cementitious urethane flooring solution, designed for light-duty applications. Applied as a 1/16″ to 1/8″ it provides an economical and durable alternative to traditional epoxy floor screeds, offering enhanced longevity and anti-slip performance.

Talk to an Expert

Quick Data

Appearance: It is a two-coat squeegee and back roller applied system with a broadcast layer between coats. This products a smooth yet anti-slip surface with a matte finish.

Applications: eurocrete LD is the most suitable alternative to conventional epoxy thin mil floor systems due to its resistance to thermal shock. Welfare areas, low traffic processing areas, Labs, and R&D facilities.

Durability: eurocrete LD has excellent chemical resistance, and its surface profile ensures slip resistance, even in wet process areas. Impervious to light impact, abrasion, and a wide range of chemicals.

Thickness: 10-20 mil thick.

Substrates: Diamond grinding preferred.

Technical Documents

Benefits

Chemical

Resistance

Physical

Resistance

Easily

Cleaned

Slip

Resistance

Physical Data

| Tensile Strength | ASTM C 307 | 2,200 psi |

| Flexual Strength | ASTM C 580 | 4,500 psi |

| Coefficient of Thermal Expansion | ASTM D 2047 | 1.1 x 10-5in/in/°F |

| Abrasion Resistance | ASTM D4 4060; CS 17 Wheel, 1000 cycles | 0.08g loss |

| Adhesion | ASTM D 4541 | 4.5 MPa (substrate facing) |

| Softening Point | 126° C | 260° F |

Cure Schedule

| Time to light traffic | 4-6 hours |

| Time to light wheels | 12-16 hours |

| Time to normal traffic | 24 hours |

Toll Free: 1-877-513-5855

Toll Free: 1-877-513-5855 eurocrete SL

eurocrete SL eurocrete TC

eurocrete TC eurocrete WR

eurocrete WR eurocrete HD

eurocrete HD